CONTACTLESS 3D METROLOGY

Machines, Software and Services targeting traceable, fast and reliable high accuracy 3D measurement in-process or near the production line

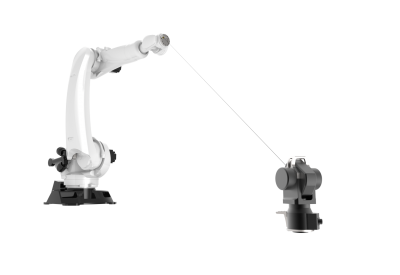

PRECISION ROBOTICS

Calibration and software solutions to optimize the performances of your robotized manufacturing processes

Our services delivery

In addition of its product line, geomnia offers a wide array of service delivery.

3D METROLOGY - PRECISION ROBOTICS

GEOMNIA possesses specific know-how and core skills in 3D metrology, software engineering, micro and nano-scale mecatronics metrology systems engineering, and process optimization by software and measuring.

Applications

Contactless 3D measurement for a faster and more reliable industry

Technologies

Several tools towards the same goal : a perfect measure

Ils nous font confiance

Geomnia collabore avec avec les plus grands groupes

News

All latest news about the company

Actualités

Finorpa & Siparex support…

FINORPA SCR and North France Amorçage (Siparex) intervened e

Actualités

PTB Certification

GEOMAX 1.0, the GEOMNIA metrological software, has received the PTB Certification (Class 1 of the smallest deviations) since its 2014 version. The PTB is the National Metrology Institute of Germany.